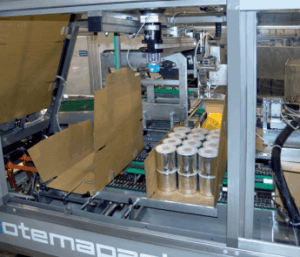

| Sotemapack wrap around WA 25 automatic case packer machines pack up to 25 packs per minute. Beginning with a flat cardboard, our machines automatically group the products and form a cardboard case around them by folding and gluing the edges. Engineered for food, beverage, and consumer products in bottles, cans, jars, detergent containers, vacuum bags, jars, and more. |

| Magazine | |

| Newly conceived modular servo driven blank magazine which enables a high speed infeed with fixed loading height. The blank magazine may be lengthened up to 8.2 feet (2,5 meters). |  |

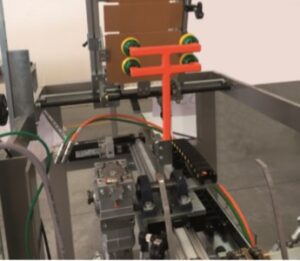

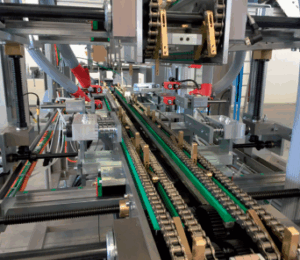

| Upper flap closing system | |

| Extended motorized upper flap closing system allowing a perfect compression of the hot melt glue at high speed. |  |

| Pick and place system | |

| Ability to stack the products via pick and place system. |  |

| Divider | |

| Divider (optional) to channel non regular/ shaped products into the correct lanes. Wide range of versions suitable to accept up to 200 products per minute. |  |

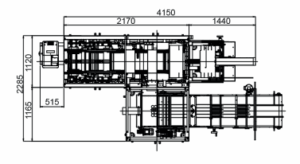

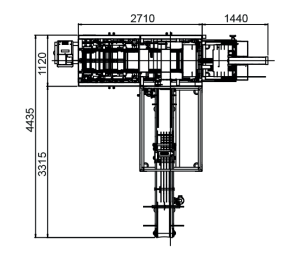

| Technical Data | |

| Power requirement: 10kW | |

| Air consumption: 200 NI-6bar | |

| Pneumatic: Camozzi | |

| PLC: Siemens S7/1500 | |

| Display: Touch Screen Siemens KTP/700 | |

| Magazin capacity: Up to 800 (3mm) (optional) | |

| Hot melt: Robatech Concept | |

| Performance: Up to 25 packs/min | |

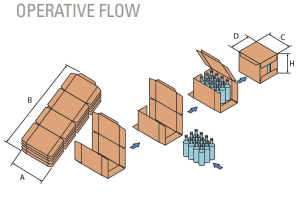

| Operative Flow |  |

| Products |  |

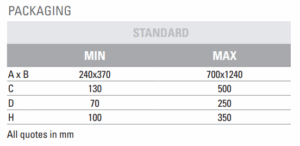

| Packaging |  |

| Technical Data |  |

| Automatic case-packer to wrap products starting from a flat blank | |

| Version with the infeed in line and parallel to the flow of the machine. Version available with *one or more in-feed lanes depending on the incoming speed of the products and on the requested collation. |  |

| Version with in-feed placed at 90° to the flow of the machine . Version available with *one or more in-feed lanes; depending on the incoming speed of the products and the requested collation. |

|

| Extended motorized upper flap closing system allowing a perfect compression of the hot melt glue at high speed. |

|

| Possibility to stack the products via pick&place system. |  |

| Divertor (optional) to channel non regular/ shaped products into the correct lanes. Wide range of versions suitable to accept up to 200 products/min. |

|

| Options and upgrades |

| Divertor to channel non regular/shaped products. |

| Automatic changeover by servomotors. |

| Stacking system via pick&place. |

| Automatic partition dispenser system. |

| Preferred components specs on request. |

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name