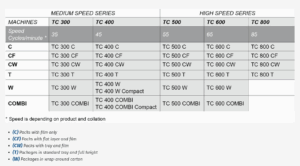

| The packaging speed of the TC series ranges from 30 to 85 packages/min. The main features of these shrink wrap machines include ergonomics, modularity, flexibility, and compact design, allowing easy change over from one format to the next.

Depending on the set-up, this case packer machine series can realize all the classic secondary packaging solutions. The design of the TC series was completely renovated and includes a new self-supporting tubular frame and large sliding doors: characteristics that facilitate access and maintenance operations, as well as ensuring complete visibility of the moving parts and of the working cycle. The automatic format change, managed through electronic movements, is performed in a very short time. |

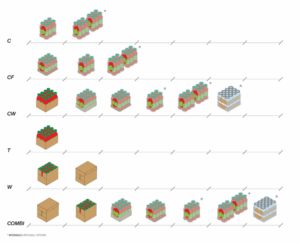

| Operating solutions |  |

| Models |  |

| External blanks magazine | |

| Developed and created to operate with the maximum comfort, the elevated ergonomics make it possible to load the blanks quickly and easily. The new structure set up orthogonally to the machine provides a great loading capacity and simplified adjustments. Based on the production speed it is possible to choose between various capacity configurations (single and double versions). |  |

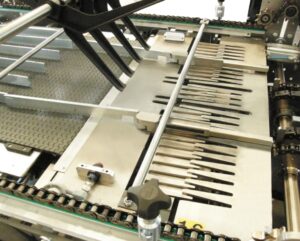

| Blanks extraction | |

| Blank extraction is carried out through a pick-up arm guided by a mechanical cam, for an ideal and precise route. The cam establishes the required rotation for the pick-up arm for better blank extraction. Unit movement is controlled by a brushless motor, the blanks are positioned on the upstroke unit in line with the machine. |  |

| Electronic product separation | |

| Continuous separation system with electronic control for medium and high speed. Product separation is carried out through a double pair of teeth, with infeed between the products from the bottom. It is very easy to make adjustments during format changes to change the product size. |  |

| Product wrapping unit | |

| Particularly suitable for high speeds or for products with an irregular shape with low stability, this device is controlled with a brushless motor and a linear guide with the function of guaranteeing correct and precise coupling of the product with the blank. |  |

| Retractable collating plate | |

| This solution offers high flexibility for the range of formats that can be produced, it also offers an excellent compromise when switching from tray packaging to packs with heat-shrink film only, and vice versa. The pneumatically-actuated surface offers the possibility of producing trays with high edges, it is particularly suited for the production of full height trays. |  |

| Product wrapping | |

| The implemented technical solutions offer great flexibility and high dimensional excursion of the product during winding from one format to another. This unit boasts multiple configuration solutions. |  |

| Film reels | |

| Various film reel positioning solutions are available, the ergonomics are particularly well-designed. Better access for format change operations and reel sealing means excellent man-machine interaction. The external reels option also offers automatic reel-change. AUTOMATIC REEL CHANGE The system seals and cuts the film in a fully-automated fashion without any operator intervention, this option makes it possible to continue without stopping film unwinding and the production cycle. The reel configuration is set up by the operator, through simple manual procedures. |  |

| Removable film unit | |

| The system offers easy access the film unit, for quick and efficient maintenance. This application is particularly suited for liquid product sectors, such as dairy and beverage, where the primary packaging may break, possibly soiling the film. |  |

| Machine frame | |

| Completely revisited, it is designed to offer multiple modular solutions based on machine configuration. The new frame offers better access to all of the units to operate the machine, change formats and perform maintenance. |  |

| Automatic format change | |

| For models with automatic format change, switching to the new format is carried out electronically through brushless motors, in most cases there is no need for tools or for the machine to be manned by the operator. Format change operations are carried out simply from the operator panel. |  |

| Specifications |

| Capacity/Speed (Packs per minute): 35-85 PPM |

| Format options: Film only, flat layer and film, tray and film, standard tray+full height, wrap around carton |

| Available options |

| Air Conditioning (Control Panel) Automatic Film Splicing Can Labelling Orientation Case Turner on Board Film Cutter Extractible Infeed Side Transfer Conveyor Remote Servicing Rockwell PLC & HMI Servo Automatic Change Over Stacker Stain Less Steel Execution UL or CSA Compliancy |

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name

“A review from a customer who benefited from your product. Reviews can be a highly effective way of establishing credibility and increasing your company's reputation.”

Customer Name